Stone, as a kind of high-grade building decoration material, is widely used in interior and exterior decoration design, curtain wall decoration and public facilities construction. At present, in the market, the common stones is natural stone, artificial stone and marble.

Stone is the most common material for buildings. So how to get stones from mountain and how to finish it for us to use in the building ?

Today, we will give you a thorough explanation from the source. Let us have a more comprehensive understanding of the whole process of stone quarries and production.

At the beginning of the exploration, stone was a part of the mountain. Every day, we watched the sunrise and sunset in the mountain, and our life was very peaceful.

02 after cutting, the original big size stones become to small , which we called it raw blocks.

03 packing and transportation, the stone quarry site selection requirements are very high. First of all, it requires convenient transportation, especially developed waterway transportation.

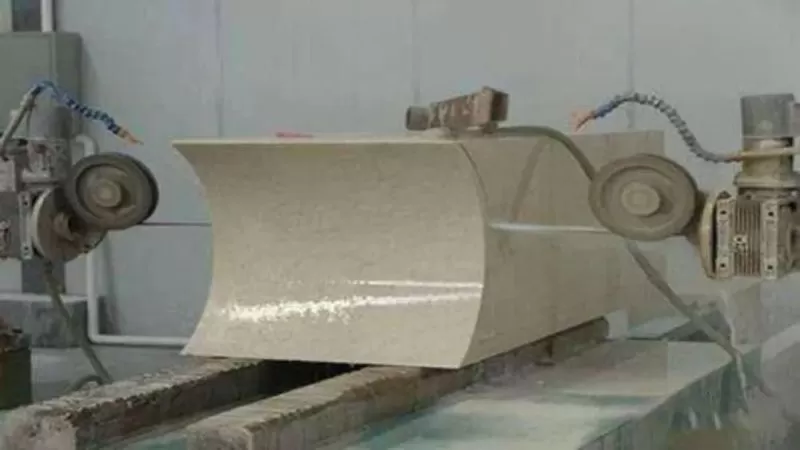

04 Gluing and cutting, in order to better cut, the stone body is brushed with thick glue (glue covered), and the uneven part of the stone is decorated (trimming), and then cut into the specified specifications.

05 glue mending (damaged glue mending, combined with fine crystalline stone particles), after the stone blocks is cut into a large size slabs, glue mending shall be carried out within 2-3 days. After drying, it is necessary to check whether there is any damage or pit on the stone surface, and it is necessary to use glue mending combined with stone debris to fill and repair.

06 cutting, (block, customized processing), good materials with good saws, cutting equipment and cutting segments quality, directly affect the quality of stone slabs

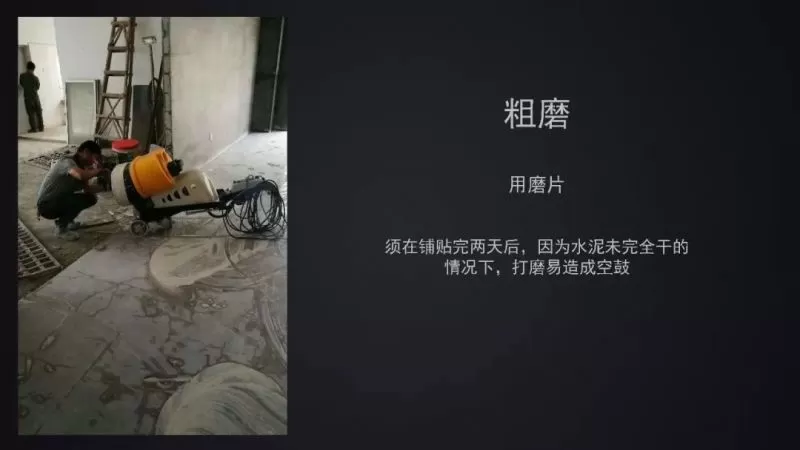

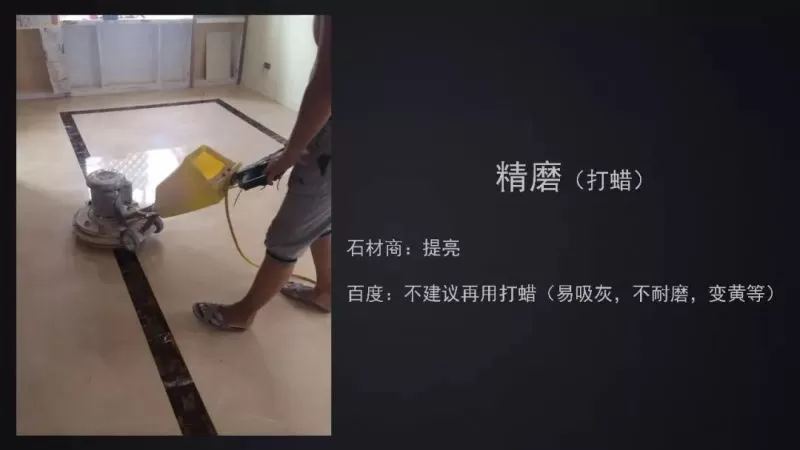

07 grinding (rough grinding, fine polishing), the technicians in the grinding and polishing process must have a pair of eyes and good listening ability. First look and second listen to judge the status of stone grinding and polishing, and whether the auxiliary materials of the machine need to be updated, etc.

08 Drying out in factory , after drying out, a row of fine stones are ready to be sent, waiting for the building to be decorated

09 protection, water-based: mainly for waterproof, water can not be touched and entered, oil-based: mainly for antifouling, stains can not be entered, and internal seepage is not allowed.

10. The transportation paving shall be carried out continuously and completed as soon as possible. After summer, it shall prevent exposure to the sun. In winter, it shall be provided with insulation measures.

11. The joint shall be glued, and the reserved joint of stone pavement shall be caulked. In principle, the joint shall be caulked with professional caulking agent, and the principle is that the caulking area will not produce alkali.

12 Polished (rough grinding, fine polishing)

13. After the maintenance, the store and hotel crystallize once every 1-2 months. Generally, professional personnel are employed for a long time.